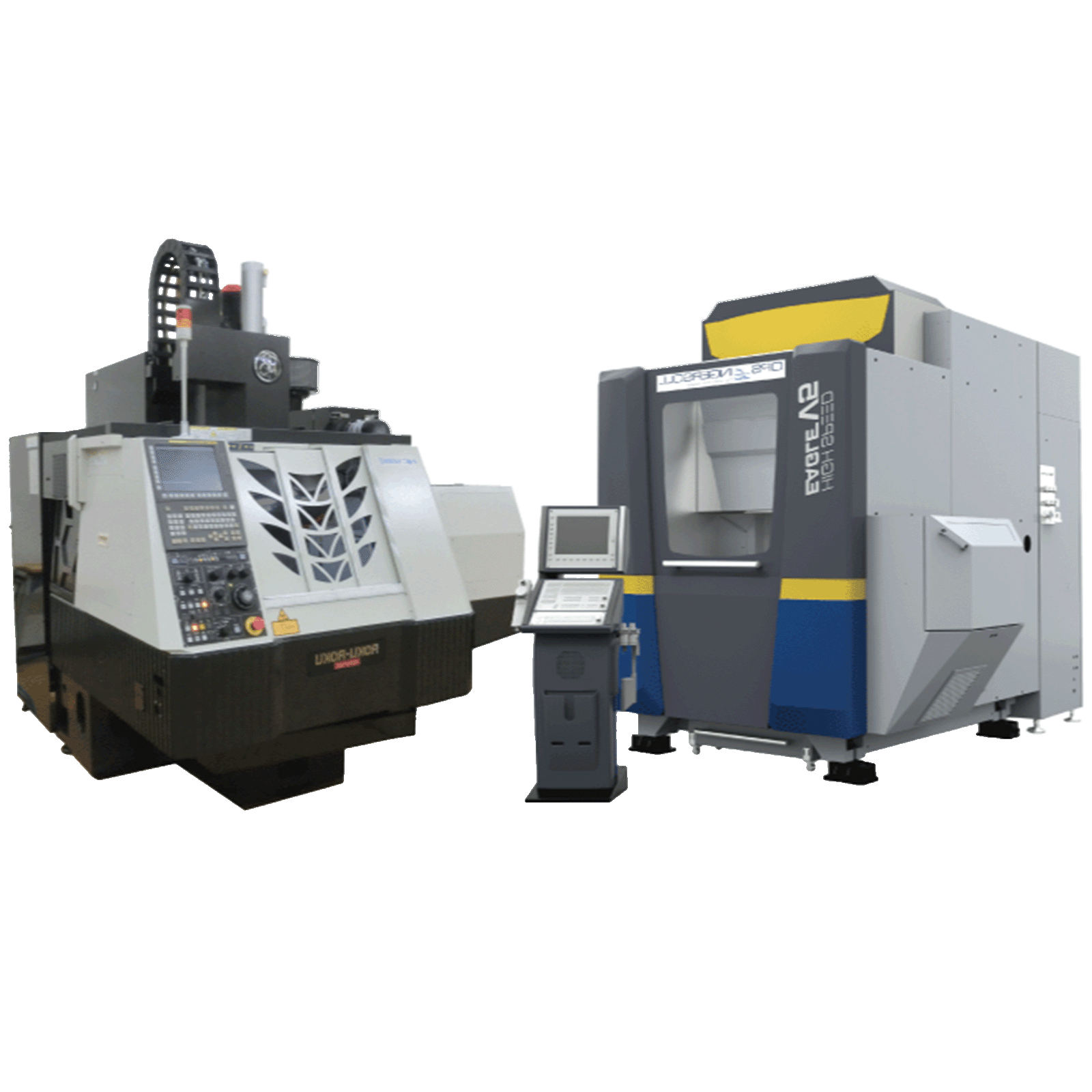

Roku-roku机器人ii

Linear technology for micron-level tolerances and excellent surface finishes.

多年来, 工具, die and mold makers have relied on 电火花 to produce 工具s in hardened steels that were difficult or impossible to machine. While 电火花 is certainly up to the job, it adds an extra step to the metal cutting process. And with the constant pressure you’re under to cut lead times and streamline processes, bt365体育娱乐觉得这一步太过了.

在高精度上提高生产率, 高质量的工作, you need a 工具 that knows how to deliver accuracy, 质量, 精度和速度都在同一时间.

The Android II is that 工具: a well-built machine that brings together the latest advances in cutting power, 工作速度, 严格的设计, heat dispersal and flexible operation to ensure precise work and high speeds.

高速生产能力

- High-speed machining technology has progressed rapidly over the last few years and is ready to take on this task using high-RPM spindles, extremely 准确的 linear motor servo drive systems, 高速机器控制器. The Android II is a machining center designed from the ground up for extremely precise, hard-steel machining at high spindle speeds and high traverse rates.

设计可靠

- The Android II’s heat-symmetric basic frame structure with a high-grade cast iron base ensures twist rigidity against spindle head motion. Its structure guarantees a reduction in thermal displacement, leading to a balance of high rigidity and a reduced weight. 两个水平相对的, flat linear motors equipped with powerful magnets ensure clearance in the side-ways, 抵消了所有的引力.

The system’s dual-layer cooling system combines direct forced-oil cooling with a wide-range jacket to separate the spindle head from the casting. 导致完全隔热, the double cooling system positioned between the heat-generating coils is matched by an in-line oil chiller unit to ensure complete control of the coolant temperature. Hot air will never collect at the spindle thanks to the Android II’s centralized exhaust and outside airflow system.

任何技术水平的人都做得很好

- 配合发那科31i-B5数控控制器, the Android II is an exceptionally well-built machine 工具 that can be operated by users of nearly any skill level. With ten (10) preprogrammed machining modes available, your operators can produce great results with unsurpassed speed and accuracy—even in the most complex 3D contours.

组件:

- X、Y、Z轴直线电机驱动系统

- Z轴热生长补偿

- Special precision roller-type linear motion ways

- 汽车润滑

- 完整的附件

- 特殊方式盖减少运动阻力

- 60000转整电机主轴

- 主轴冷却

- Non-contact 工具 measurement (Blum laser) with air blow

- 53加仑(200L)冷却液罐

- 20位自动换刀器

- X, Y和Z轴(0.5纳米(分辨率)线性尺度

- 工具紧固块

- 自动断电电路

- 工作清洗枪

- 空气吹扫

- 4寸彩色显示器

- 2级巡逻灯(黄、红)

- 手动进给

- 一个机器灯(LED)

- 工具箱

- 维护设备

- 调平螺栓和垫板

用户界面:

Fanuc 31i-B5控制功能

- 超级PC X +功能(10种模式操作)

- AI Contour Control II, high-speed processing, nano smoothing, and look-ahead block expansion

- Editable data server with 2GB program storage (flash card type)

- 以太网与TCP/IP协议 & RS232通信

- 320米内存(128KB)

- 160米内存(64KB)

- 自定义宏B

- 部分数 & 运行时间显示

- 螺旋插补

| 模型 | 安卓二世 |

|---|---|

| 机器行程:X X Y X Z in (mm) | 17.7 x 13.8 x 7.9 (450 x 350 x 200) |

| 主轴转速 | 3000 ~ 60000 RPM |

| 工作台尺寸X- Y: in (mm) | 21.6 X 13.8 (550 X 350) |

| 主轴惠普 | 5.0 |

| 主轴润滑 | 油雾 |

| 主轴锥度 | 1/10锥度(双平面约束) |

| 刀柄 | HSK-E25 |

| 换刀器尺寸 | 20位标准(可选:40、60、100) |

| 定位精度/重复性:in (μm) | ±0.000039/±0.0000079 (±1.0/±0.2)全行程 |

| 工作台到主轴机头距离:in (mm) | 3.15 ~ 11.02 (80 ~ 280) |

| 马克斯. 工件重量:lb (kg) | 220 (100) |

| 桌距地面高度:单位(毫米) | 29.5 (750) |

| 定位精度:in (μm) | ±0.00006 (±1.5) |

| 主轴空气吹扫 | 标准 |

| 经主轴吹风 | NA |

| 带收集器的油雾 | 可选 |

| 线性尺度X, Y, Z轴 | Heidenhain 0.002µm (2nm)标准 |

| 快速遍历速度:in/min. (米/分钟.) | 590 (15) |

| 切割速度(普通模式):in/min. (毫米/分钟.) | 0.04 – 394 (1 ~ 10,000) |

| 切割速度(GR Super PC模式):in/min. (米/分钟.) | 590 (15) |

| 集尘系统 | NA |

| 冷却液罐容量:加仑(L) | 52.8 (200) |

| 机器重量:lb (kg) | 12,787 (5800) |

| 机器高度:in (mm) | 94.9 (2410) |

| 所需占地面积[马赫. 单位]:in (mm) | 83.0 x 113.4 (2110 x 2880) |

| 控制单元 | Fanuc 31i-B5 Super High-Speed Processor and Al Contour Control II and Super PC X Function |

| 功率要求KVA | 200 ~ 220V 19.0 kVA |

| 空气供给 | 9 cu.ft./min≤72 psi |

相关解决方案

-

五轴加工技术

High-speed, high-precision machines with the power and flexibility to meet any challenge.

了解更多 -

直线驱动技术

Hyper-准确的 machinability for tight tolerances and micro-fine work where the details really matter.

了解更多 -

高速加工

Top-of-the-line machinery with added cooling power for consistent performance on mission-critical tasks.

了解更多 -

石墨制造

Multiple solutions and expertise in making graphite electrodes.

了解更多 -

铣削自动化

Multiple solutions and expertise in making graphite electrodes.

了解更多

-

"Not only does the 5-axis capability of the OPS Ingersoll Eagle V5 milling machine enable us to burn parts with less physical electrodes, it also has a robotic 工具 changer so we can focus more during the day on things that need constant attention."

布拉德·麦克道尔, 质量工具 & 死的总统 阅读案例分析 -

-

"The Eagle 800 has burn technology that gives us a competitive advantage because it takes about half the time to burn and uses fewer electrodes, 这样既节省时间又节省金钱. Our goal is to run it all day and all weekend. I like that we also are cutting down on our carbon footprint by using fewer graphite electrodes and less copper wire than before."

史蒂夫(, 零容忍总统 查看案例研究 -

"We used to struggle with 工具 deflection on deep cuts. Now we’re able to tip that up in a five axis and actually hit on the bottom of the flute. And we’re not getting that 工具 push anymore. 电极要精确得多."

乍得卡恩斯, 质量工具 & 我是副总裁 阅读案例分析 -

-

"The kinematics of the Roku-Roku VMCs allow us to run faster feed rates and not sacrifice surface finish or accuracy. The machines are efficient in terms of increased cutter life, reliable Fanuc control and overall machine stability. We can run longer intervals on downstream inspection on parts that the Roku-Rokus machined."

约翰TerBeek, 特贝克模塑公司的合伙人 & 工具 查看案例研究