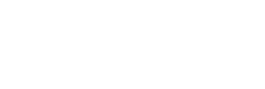

三菱AZ600

建设未来.

Since introducing its first metal laser cutting machine in 1977, Mitsubishi 电 has been a leader in laser systems. The latest additive manufacturing offering is a wire-laser metal 3D printer, the AZ600.

The 三菱AZ600 melts welding wire with a laser beam to create high-quality 3D structures, 生产的高速, high-precision 3D printing while reducing energy consumption and waste.

Applications include rapid prototyping, 模具和模具, 昙花一现的人物, 短时间运行, 大规模生产, 维护, 修复, 工具和更多.

With the same proprietary wire-feeding technology used in Mitsubishi’s industry-leading wire 电火花s, a simple command on the machine’s CNC control feeds the exact amount of wire to the target location. Unlike other 3D printers, the wire is in the front of the machine to make it easier to replace.

其他主要特点:

线-laser metal 3D printing is a more efficient and versatile process than powder-based metal 3D printing. It offers a number of advantages, including higher deposition rates, 更好的表面光洁度, 减少孔隙度, better mechanical properties and reduced powder waste.

另外, wire-laser metal 3D printing is much safer to operate because it doesn’t use potentially flammable and explosive powder. And because wire-laser metal 3D printing is a closed system, the metal powder is contained within the printer, reducing the risk of operator exposure.

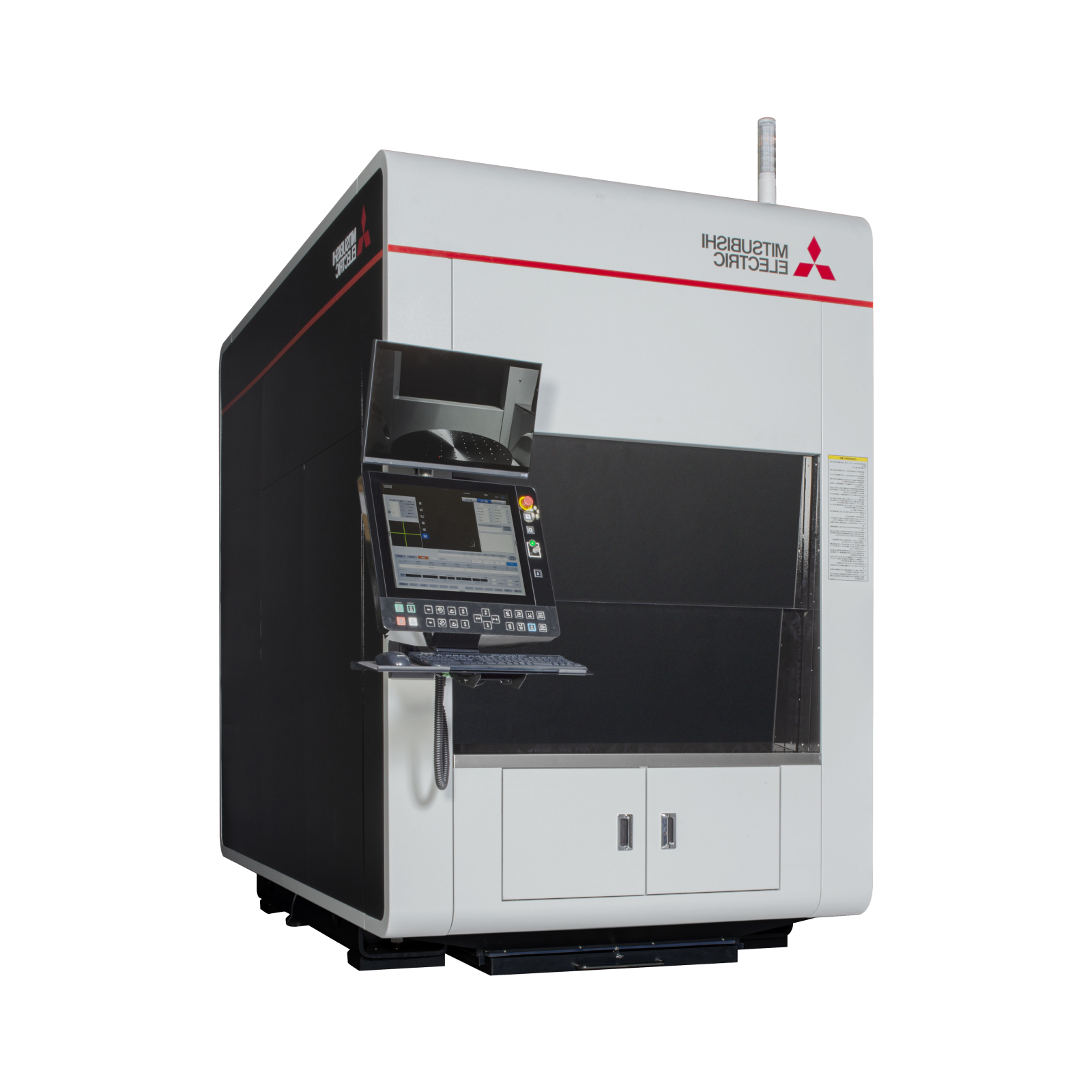

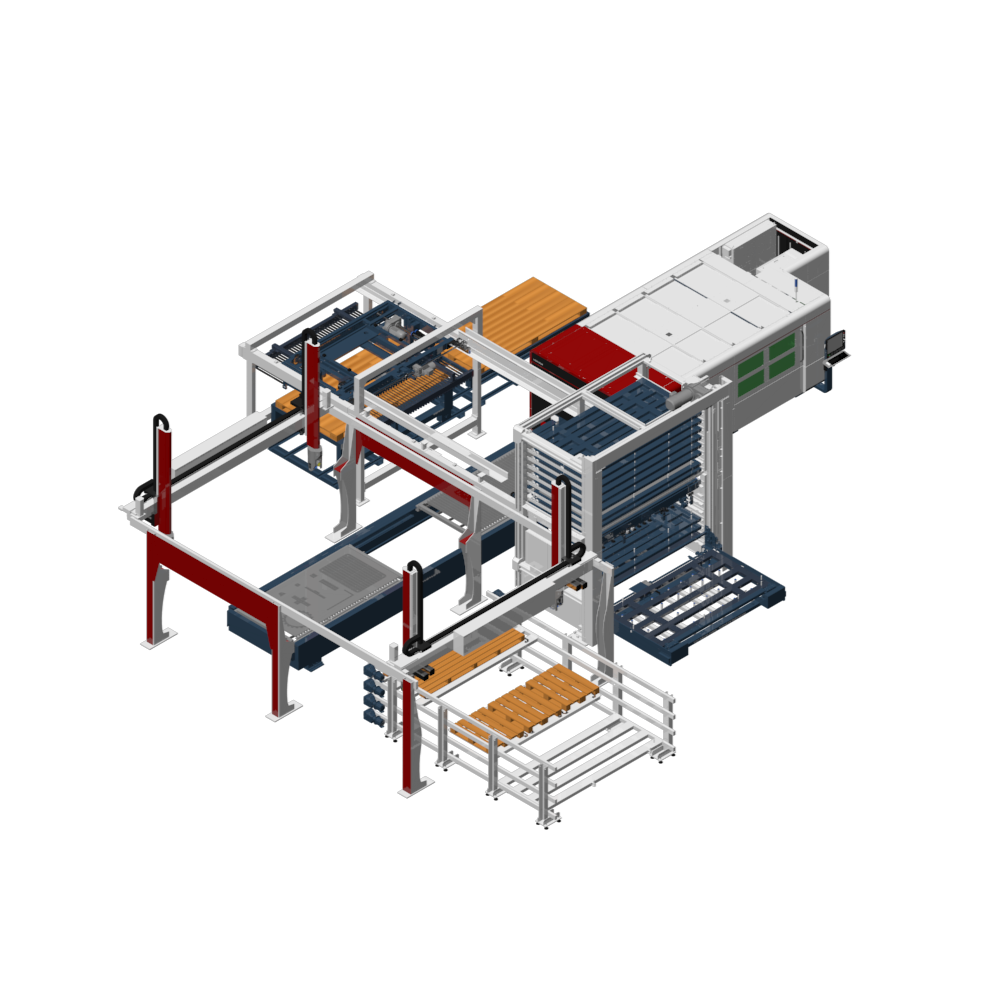

相关解决方案

Are you searching for a specific solution to fill that empty spot on your shop floor? Do you need to build integrated manufacturing cells from the ground up? You’re in the right place. Our expertise spans virtually every aspect of metalworking.