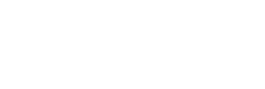

鹰V9C (5-AXIS带冷却系统)

一个灵活的, automation-ready, 5-axis machining solution for ultra precision machining with a coolant system.

The Eagle V9C (5-axis) is an ultra precision machining center with coolant system. The V9C is designed to be an ultra-rigid 5-axis vertical machining center with the capacity to handle a 1,100磅重的工件在23上.6寸台面. The Heidenhain TNC-640 control unit is mounted on a moveable pedestal for optimal positioning convenience. The Eagle V9C is designed with a side opening in the casting to allow robot loading from the right side with pallets up to 19.7”广场.

如果你在找一个健壮的, 强大的工具,很容易访问, 操作, 和调整, all so you can better deliver top-tier products quickly and cost-effectively, 那bt365体育娱乐就有好消息了. 鹰V9C可能是灵活的, functional 5-axis milling machine with temperature controlled coolant system for you.

专为长期使用而设计

- 以耐用, high-rigidity internal components that can take a beating, the Eagle V9C offers superior performance with minimum downtime so you can stay productive and profitable.

小包装中的大实用程序

- 鹰V9C(冷却剂版本)提供了一个大, 易于进入的工作区域在一个小的尺寸, 结合其强大的机载数控控制, allows workers of nearly any skill level to create top-quality results without requiring much floorspace.

自带支持

- The Eagle V9C might look a little different than our other machines (the blue and yellow color scheme is a bit of a giveaway), but our highly responsive service department still knows it inside and out. You can always count on us to help keep you up and running.

功能:

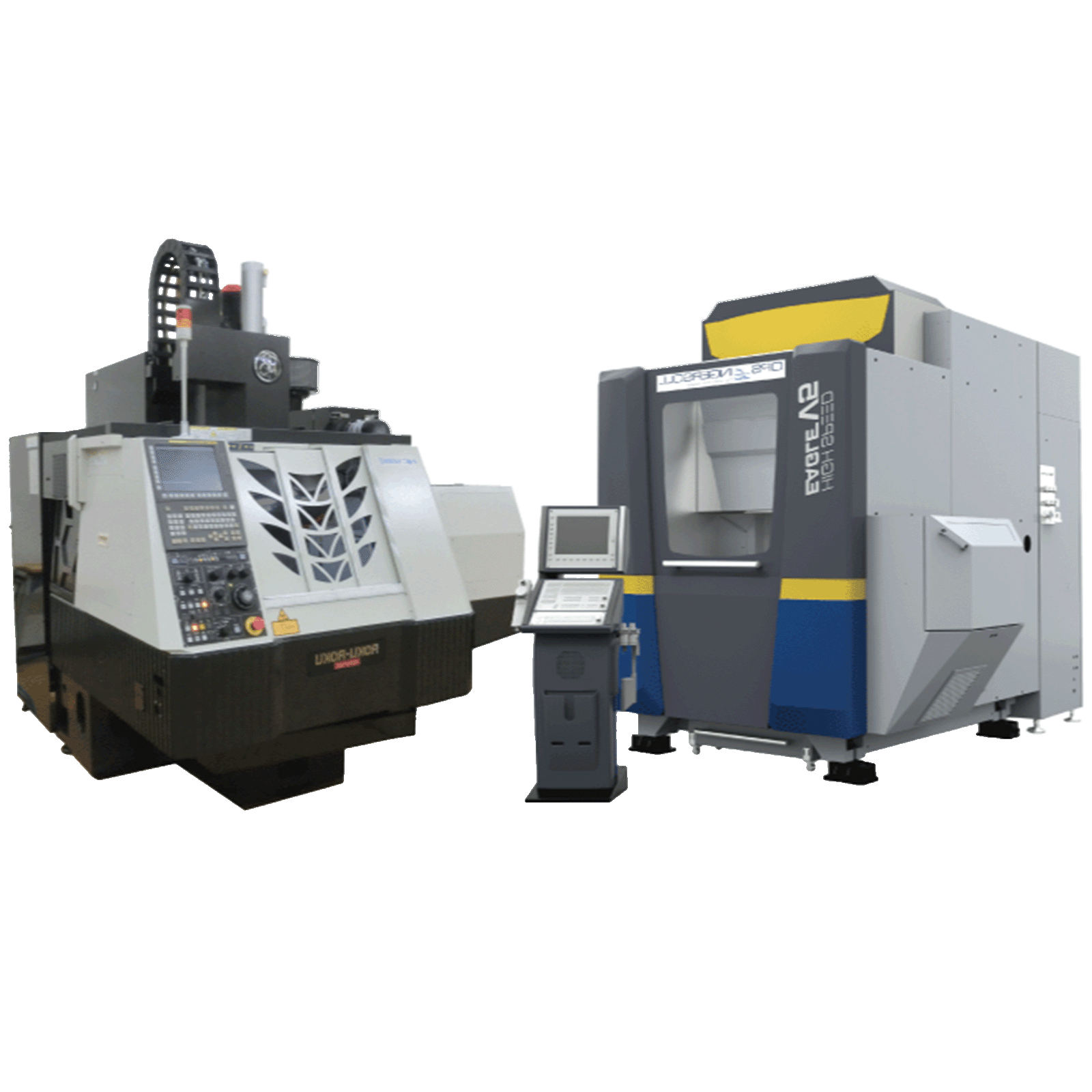

- The Eagle V9C (Coolant Version) gantry-type 5-axis machining center is built and designed to be highly rigid and incredibly precise

- 达到高刚性和精细光洁度, the Eagle V9C employs a U-shape polymer concrete base, with B-axis support and a high-quality rotary table C-axis

- 它还配备了高马力, 26,000转/分综合主轴, 重型, 滚柱式直线导轨, and a dual gantry drive (two ball screws and two linear glass scales) in both the X and Y axis

- The Eagle V9C is capable of performing high-precision cuts with the X, Y, Z, B, 和c轴同时移动

- 斜面加工, 螺旋轮廓加工, 不规则轮廓加工, and other complex cutting tasks can be made simple with the Eagle V9C

- The Eagle V9C’s B-axis uses a zero-backlash gear drive while the C-rotary axis utilizes a direct drive motor, complemented with direct rotary encoders—this is superior to the conventional “worm gear” setup in drive transmission and power efficiencies

- 旅行:X, Y和Z: 31.5” x 23.62” x 19.69”

- 快速导线:1181 in/min. (X, Y, Z)

- 加速度:49英尺/秒²(1.5G)

组件:

- Precision Package 3 for 5-axis machines – Temperature-distribution compensation, including:

- 自动温度漂移控制

- 五轴补偿

- 海德海恩选件(运动学可选)

- 运动协调陶瓷球

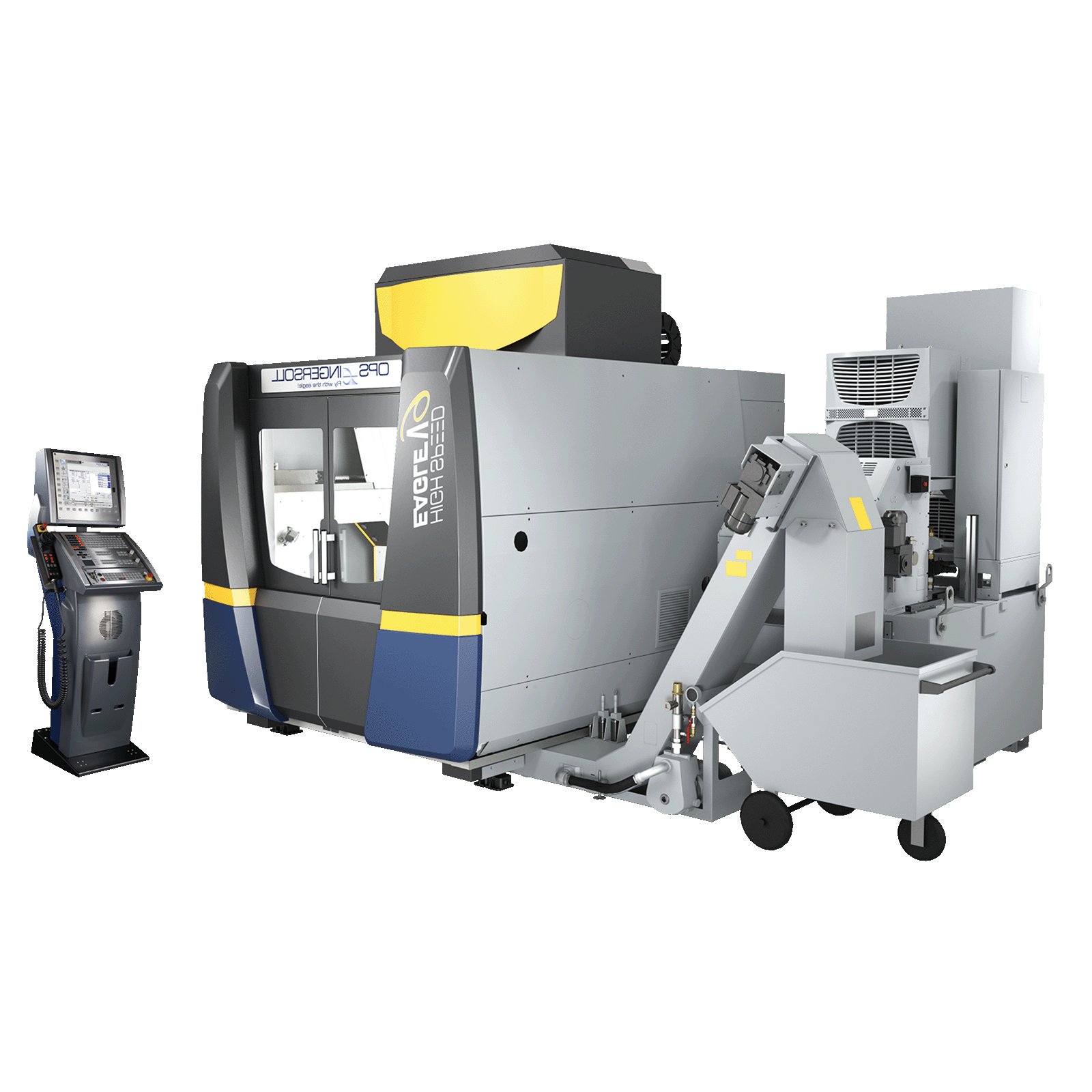

- P3 185加仑冷却剂系统包括

- 机器准备用水

- 警察过滤器

- 带式滤纸

- 刮板链输送机

- 工作区域冲洗

- 580 PSI直通工具冷却剂

- 吹气系统主轴外部(145 psi)

- 集成4/5轴系统(无t型槽工作台)

- 高频主轴40.2 HP, 26000转, HSK-A63, 48-pos ATC

- 雷尼绍红外测量探头

- Blum laser system for tool breakage detection and tool length/diameter compensation

- 双龙门驱动,X轴和Y轴

- 高分子混凝土减振机床

- 3点基础设置/找平

- 滚珠丝杠与直接驱动交流电机

- 玻璃刻度绝对测量(空气净化)

- 自动润滑系统,包括驱动和方式

- 全衬里防尘和防液

- 工件托盘系统面板准备

可选配件:

- 18,000 RPM, 47 HP HSK-A63主轴(48位ATC)

- 36000转,21.5 HP HSK-E50主轴(72位ATC)

- 200工具外部存取系统

- 工具 Cleaning Station for use with Blum 激光 工具 Measurement

- P6 317 gallon Coolant System with 1160 PSI Thru 工具 Coolant

- ICS Vario Valve (Variable thru tool Coolant Function)

- Table clamping and pallet systems from EROWA, Hirschmann, and system 3R

- ICS 2 ATS internal coolant supply with aerosol/dry lubrication

- T-Slot table to cover the 4/5-axis (Converts the machine to 3-axis operation)

- 油雾吸入装置

- 芯片桶

- 冷却剂冷却

- 三色状态灯

- 动态碰撞监测

- 多变化简易基本单元(包括:抓手, 40点或5点或4点杂志, 工件更换处, 以及与机器的连接)

用户界面:

- Heidenhain TNC-640 HSCi 5-axis simultaneous control includeing:

- 带有软键的15英寸TFT彩色平板显示器

- HEROS机器控制实时操作系统

- 5000街区展望

- 5ms块处理速度(120,000 BPM)

- 高级编程周期

- 工具抵消

- 标准语言

- Heidenhain 4/5轴选项

- 手轮hr410超级位置

| 机器行程:X X Y X Z in (mm) | 31.5 x 23.6 x 19.7 (800 x 600 x 500) |

|---|---|

| a轴倾斜范围度(RPM) | -60 ~ 140° (25) |

| c轴旋转范围(RPM) | 360° (100) |

| 转盘面板:直径. (mm) | 23.6 (600) |

| 最大工件高度:面板/托盘(mm) | 21.6/19.7 (550/500) |

| 最大转盘盖:lb (kg) | 1,100 (500) |

| 主轴转速 | 26000转 |

| 主轴转速控制./ 30min (kw) | 26.8/40.2 HP (20.0/30.0 kw) |

| 主轴头到工作台:in (mm) | 2.75 ~22.4 (70 ~600) |

| 更换工具选择 | HSK-A63(总分48分) |

| 快速速度:单位/分钟(m/min) | 1,181 (30) |

| 最大工件3轴英寸/磅(mm/kg) | 31.5 x 23.6 x 19.7 /4,400 (800 x 600 x 500 /2,000) |

| 机器重量:lb. (kg) | 25,353 (11,500) |

| 尺寸W-D-H: in (mm) | 85.7 x 120.6 x 112.2 (2,180 x 3,060 x 2,850) |

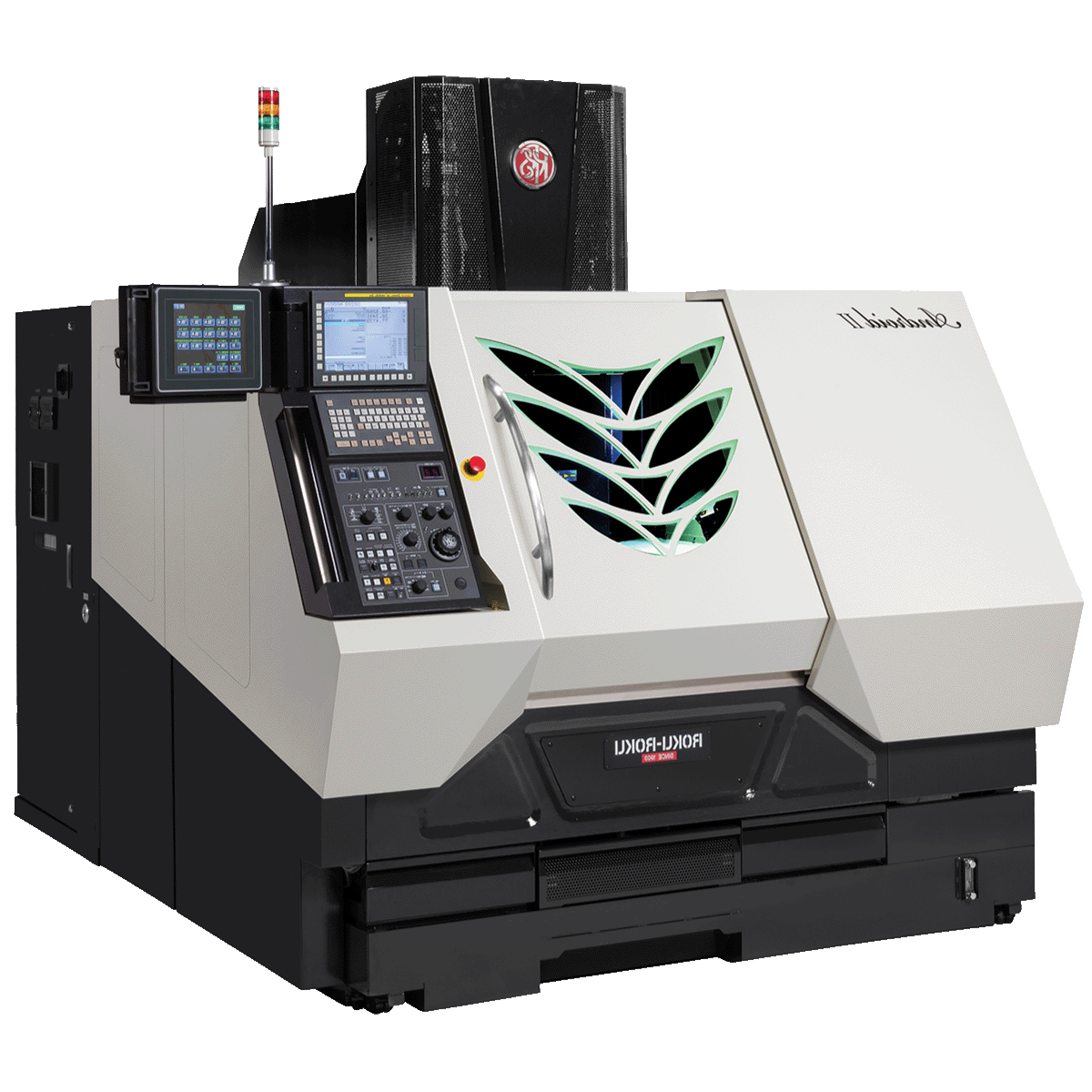

相关解决方案

-

五轴加工技术

高速, high-precision machines with the power and flexibility to meet any challenge.

了解更多 -

直线驱动技术

Hyper-准确的 machinability for tight tolerances and micro-fine work where the details really matter.

了解更多 -

高速加工

Top-of-the-line machinery with added cooling power for consistent performance on mission-critical tasks.

了解更多 -

石墨制造

Multiple solutions and expertise in making graphite electrodes.

了解更多 -

铣削自动化

Multiple solutions and expertise in making graphite electrodes.

了解更多

-

"Not only does the 5-axis capability of the OPS Ingersoll Eagle V5 milling machine enable us to burn parts with less physical electrodes, it also has a robotic tool changer so we can focus more during the day on things that need constant attention."

布拉德·麦克道尔, 质量工具 & 死的总统 阅读案例分析 -

-

"The Eagle 800 has burn technology that gives us a competitive advantage because it takes about half the time to burn and uses fewer electrodes, 这样既节省时间又节省金钱. bt365体育娱乐的目标是整天和整个周末都跑. I like that we also are cutting down on our carbon footprint by using fewer graphite electrodes and less copper wire than before."

史蒂夫(, 零容忍总统 查看案例研究 -

-

-

"The kinematics of the Roku-Roku VMCs allow us to run faster feed rates and not sacrifice surface finish or accuracy. The machines are efficient in terms of increased cutter life, 可靠的发那科控制和整机稳定性. We can run longer intervals on downstream inspection on parts that the Roku-Rokus machined."

约翰TerBeek, 特贝克模塑公司的合伙人 & 工具 查看案例研究